Smart Automation Systems for Industry 4.0

- 0

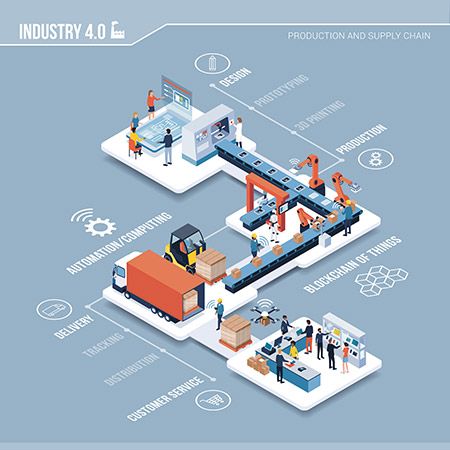

In the era of Industry 4.0, technology is constantly evolving to make manufacturing processes more efficient and cost-effective. One of the key advancements in this field is the development of smart automation systems. These systems use cutting-edge technology such as artificial intelligence, machine learning, and IoT (Internet of Things) to streamline production processes and increase productivity.

What are Smart Automation Systems?

Smart automation systems are a combination of hardware and software that work together to automate various tasks in a manufacturing environment. These systems can be programmed to perform tasks such as monitoring equipment performance, adjusting production schedules, and even predicting maintenance needs before they arise. By using a combination of sensors, actuators, and advanced algorithms, smart automation systems can make real-time adjustments to optimize production efficiency and reduce downtime.

The Benefits of Smart Automation Systems

There are many benefits to implementing smart automation systems in an Industry 4.0 manufacturing environment. One of the biggest advantages is the ability to increase productivity and reduce costs. By automating routine tasks, manufacturers can free up human workers to focus on more complex and value-added activities. This can lead to faster production times, higher quality products, and ultimately, increased profits.

Another key benefit of smart automation systems is their ability to improve safety in the workplace. By reducing the need for human workers to perform dangerous or repetitive tasks, smart automation systems can help prevent accidents and injuries. This not only protects workers but also ensures a more reliable and consistent production process.

Key Features of Smart Automation Systems

Smart automation systems come equipped with a range of features that set them apart from traditional automation systems. Some of the key features include:

Real-time monitoring and analysis of production data

Predictive maintenance capabilities to reduce downtime

Integration with other smart technologies such as AI and IoT

Adaptive control algorithms to optimize production processes

User-friendly interfaces for easy programming and monitori

Examples of Smart Automation Systems in Action

There are many real-world examples of smart automation systems being used in Industry 4.0 settings. For instance, a smart warehouse system can automatically track inventory levels, optimize storage space, and even coordinate delivery schedules with suppliers. In a smart manufacturing plant, robots equipped with sensors can work alongside human workers to assemble products, perform quality control checks, and even automatically reorder supplies when inventory is running low.

Smart automation systems are revolutionizing the manufacturing industry by making production processes more efficient, cost-effective, and safe. By harnessing the power of advanced technologies such as AI, machine learning, and IoT, manufacturers can optimize their operations and stay ahead of the competition in the fast-paced world of Industry 4.0. As the demand for smart automation systems continues to grow, it is clear that they will play a key role in shaping the future of manufacturing for years to come.