Manufacturing Tools and Supplies for Enhanced Efficiency

- 0

In the fast-paced world of manufacturing, efficiency is key. With the constant demand for high-quality products, quick turnaround times, and cost-effective solutions, manufacturers are always on the lookout for tools and supplies that can help streamline their processes and boost productivity. From cutting-edge machinery to innovative software, there are a wide range of products available that can help take your manufacturing operations to the next level.

Advanced Machinery for Precision Manufacturing

One of the most important investments a manufacturer can make is in advanced machinery. Whether you are in the automotive, aerospace, electronics, or any other manufacturing industry, having the right tools can make a world of difference in terms of efficiency and quality.

CNC machines, for example, are a staple in modern manufacturing facilities. These computer-controlled machines can perform a wide range of tasks with incredible precision, from cutting and milling to drilling and shaping. By automating these processes, manufacturers can reduce the risk of human error and produce more consistent, high-quality products.

Another essential tool for precision manufacturing is 3D printing technology. This revolutionary technology allows manufacturers to create complex parts and prototypes with incredible speed and precision. By building up layers of material, 3D printers can produce objects with intricate designs that would be impossible to create using traditional manufacturing methods.

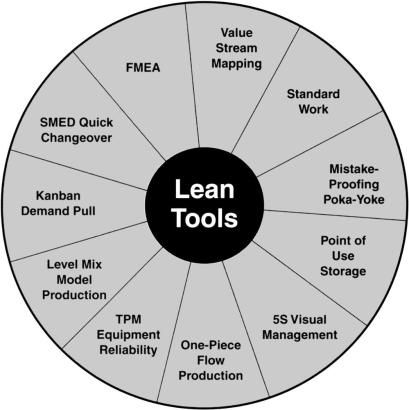

Innovative Software for Streamlining Processes

In addition to advanced machinery, manufacturers can benefit from using innovative software to streamline their processes. From inventory management systems to scheduling software, there are a wide range of tools available that can help manufacturers optimize their operations and reduce waste.

For example, ERP (Enterprise Resource Planning) software can help manufacturers track and manage all aspects of their business, from production and inventory to finance and human resources. By integrating data from various departments, ERP systems can provide a comprehensive view of the entire manufacturing process, allowing managers to make more informed decisions and identify areas for improvement.

Another useful tool for manufacturers is CAD (Computer-Aided Design) software. This software allows engineers and designers to create detailed 3D models of products and components, which can then be used to optimize the manufacturing process and reduce time-to-market. By simulating different scenarios and making adjustments in the virtual space, manufacturers can identify potential issues before they arise and make necessary changes to improve efficiency.

Essential Supplies for a Well-Equipped Manufacturing Facility

In addition to advanced machinery and innovative software, manufacturers also need a wide range of supplies to keep their operations running smoothly. From cutting tools and abrasives to safety equipment and cleaning supplies, having the right supplies on hand is essential for maintaining a safe and efficient manufacturing environment.

Cutting tools, such as drills, end mills, and reamers, are essential for machining operations and can make a big difference in terms of efficiency and accuracy. By using high-quality cutting tools made from durable materials, manufacturers can reduce tool wear and produce more consistent results.

Safety equipment is another essential supply for any manufacturing facility. From goggles and gloves to ear protection and respirators, having the right safety gear can help protect workers from injury and ensure a safe working environment. By investing in high-quality safety equipment, manufacturers can reduce the risk of accidents and create a more productive workplace.

In conclusion, manufacturers can enhance their efficiency by investing in advanced machinery, innovative software, and essential supplies. By leveraging cutting-edge technology and tools, manufacturers can streamline their processes, reduce waste, and improve the quality of their products. Whether you are a small-scale operation or a large manufacturing facility, investing in the right tools and supplies can make a big difference in your overall efficiency and competitiveness in the market.