Innovative Robotics for High-Performance Industrial Applications

- 0

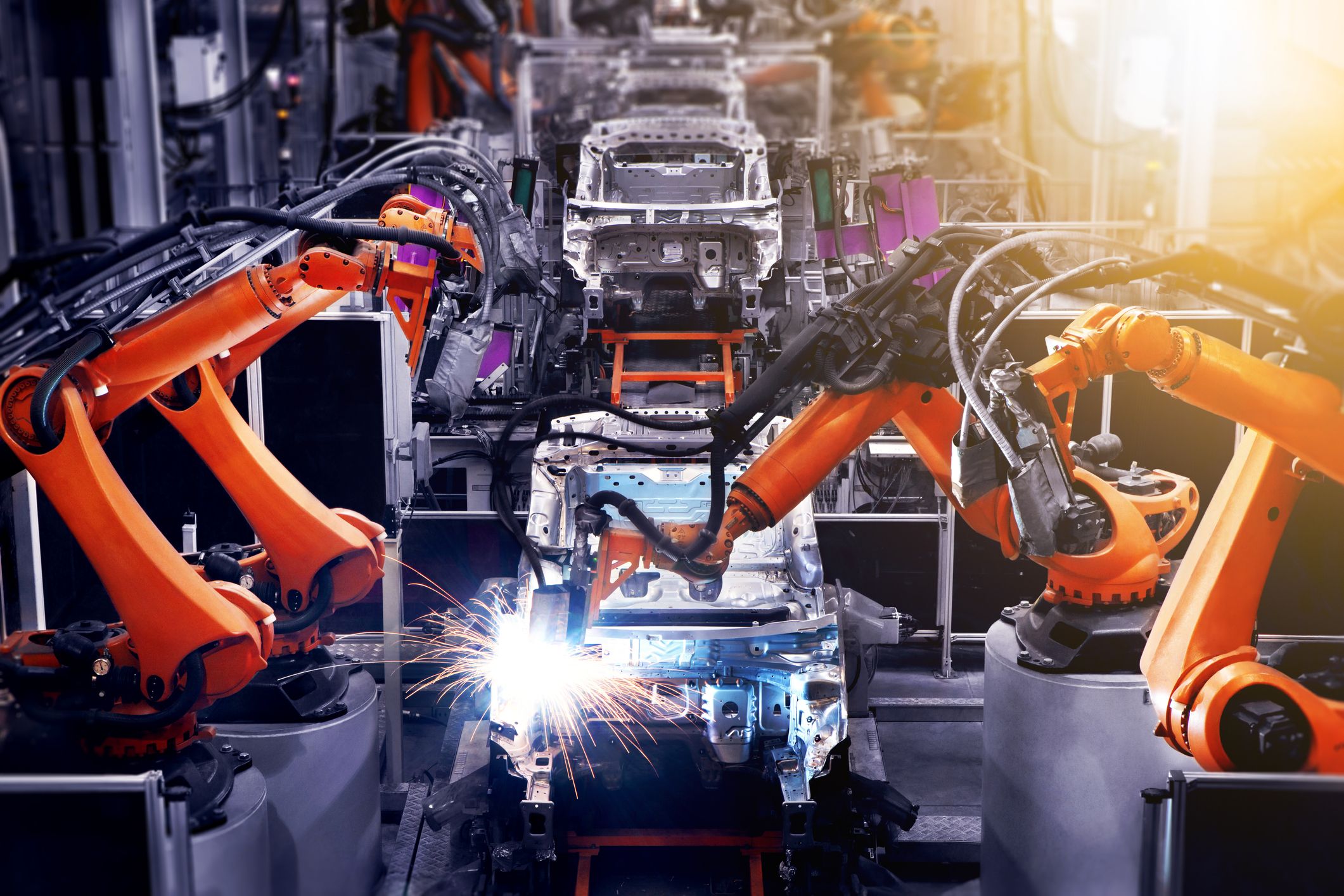

Robotics technology has revolutionized the industrial sector, offering efficient, precise, and cost-effective solutions for a wide range of applications. From automotive manufacturing to food processing, robots have become an integral part of modern industrial processes. Today, innovative robotics systems are pushing the boundaries of what is possible, enabling high-performance and advanced capabilities that were once thought impossible.

The Evolution of Robotics in Industry

Over the years, robotics technology has evolved significantly, from simple programmable machines to highly sophisticated autonomous systems. Advances in artificial intelligence, machine learning, and sensor technology have enabled robots to perform complex tasks with precision and efficiency. Today’s industrial robots are capable of tasks such as welding, painting, assembly, and even quality control.

The Benefits of Innovative Robotics

The use of innovative robotics in industrial applications offers a wide range of benefits, including:

Increased Efficiency: Robots can perform repetitive tasks at a much faster rate than humans, leading to increased productivity and efficiency.

Improved Accuracy: With advanced sensor technology, robots can perform tasks with incredible precision, reducing errors and waste.

Enhanced Safety: By taking on dangerous or hazardous tasks, robots help to improve workplace safety for human workers.

Cost-Effectiveness: While the initial investment in robotics technology may be significant, the long-term cost savings are often substantial due to increased productivity and reduced waste.

Applications of Innovative Robotics

Innovative robotics technology is being used in a wide range of industrial applications, including:

Automotive Manufacturing: Robots are used for tasks such as welding, painting, and assembly in the automotive industry, improving efficiency and quality control.

Food Processing: Robots are utilized for tasks such as packaging, sorting, and quality inspection in the food processing industry, ensuring consistency and hygiene standards.

Pharmaceuticals: Robots are used for tasks such as dispensing medications, labeling, and packaging in the pharmaceutical industry, ensuring accuracy and efficiency.

Logistics and Warehousing: Robots are used for tasks such as inventory management, picking, and packing in logistics and warehousing operations, increasing efficiency and order accuracy.

The Future of Robotics in Industry

The future of robotics in industry looks incredibly promising, with ongoing advancements in technology leading to even more innovative and high-performance solutions. As robotics technology continues to evolve, we can expect to see robots taking on more complex tasks, working alongside humans in collaborative environments, and delivering even greater levels of efficiency and precision.

Ultimately, innovative robotics for high-performance industrial applications are shaping the future of manufacturing and production, offering a glimpse into a world where automation and technology drive productivity and innovation. As industries continue to embrace robotics technology, the possibilities for efficiency, quality, and safety are endless.

For businesses looking to stay ahead in a competitive market, investing in innovative robotics technology is no longer a luxury but a necessity to drive growth and success in the ever-evolving industrial landscape.