Industrial-Grade Tools for Precision Manufacturing

- 0

When it comes to precision manufacturing, having the right tools can make all the difference. Industrial-grade tools are designed to meet the demands of high-precision work and provide the reliability and accuracy needed for today’s advanced manufacturing processes. From machining to 3D printing, these tools are essential for producing high-quality, precise products. In this article, we will explore some of the top industrial-grade tools used in precision manufacturing.

Machining Tools

One of the key tools in precision manufacturing is the machining tool. These tools are used to shape and cut various materials with high precision. CNC machines, milling machines, and lathes are common examples of machining tools used in precision manufacturing. These tools are designed to operate with high accuracy and consistency, making them essential for producing intricate and detailed parts.

CNC Machines

CNC machines, or Computer Numerical Control machines, are a staple in precision manufacturing. These machines are programmed to control the movement of the cutting tools with precision and accuracy. By using computer-aided design (CAD) software, operators can create complex designs that are then translated into precise movements by the CNC machine. This results in consistent and high-quality production of parts.

Milling Machines

Milling machines are another essential tool in precision manufacturing. These machines use rotary cutting tools to remove material from a workpiece, creating complex shapes and designs with precision. Milling machines can be used for a wide range of materials, including metal, plastic, and wood. With their ability to produce intricate details and tight tolerances, milling machines are a vital tool in precision manufacturing.

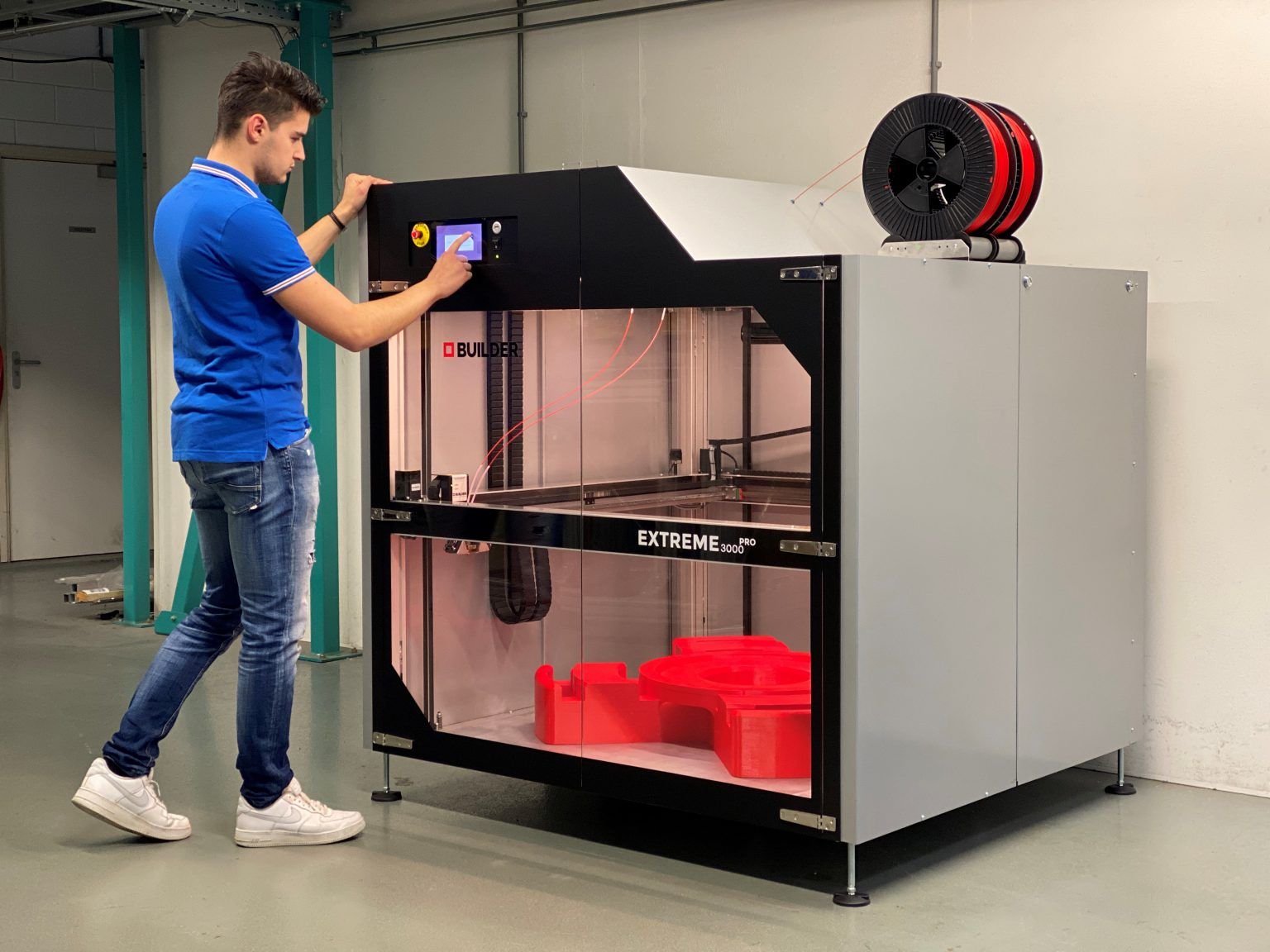

3D Printing

3D printing, also known as additive manufacturing, is a cutting-edge technology that is revolutionizing precision manufacturing. This technology uses a layer-by-layer approach to create three-dimensional objects from digital designs. 3D printers can produce complex and intricate parts with high levels of accuracy, making them ideal for rapid prototyping and small batch production.

Stereolithography (SLA) 3D Printers

Stereolithography, or SLA, is a type of 3D printing technology that uses ultraviolet light to solidify liquid resin into a solid object layer by layer. SLA printers are capable of producing highly detailed and accurate parts with smooth surfaces. This makes them a popular choice for precision manufacturing applications where intricate designs and tight tolerances are required.

Fused Deposition Modeling (FDM) 3D Printers

Fused Deposition Modeling, or FDM, is another common 3D printing technology used in precision manufacturing. FDM printers extrude thermoplastic material layer by layer to build up a three-dimensional object. These printers are known for their reliability and cost-effectiveness, making them a popular choice for producing functional prototypes and end-use parts in precision manufacturing.

Measurement Tools

Accurate measurement is essential in precision manufacturing to ensure that parts meet the specified tolerances and dimensions. Precision measurement tools, such as calipers, micrometers, and laser scanners, are used to verify the quality and accuracy of manufactured parts. These tools provide precise measurements and feedback that help manufacturers produce high-quality products consistently.

Digital Calipers

Digital calipers are a versatile tool used in precision manufacturing for measuring the dimensions of objects with high accuracy. These handheld devices provide quick and accurate measurements of length, width, and depth. Digital calipers have a digital display that shows the measurement with high precision, making them ideal for checking the dimensions of machined parts and components.

CMM Machines

Coordinate Measuring Machines, or CMM machines, are advanced measurement tools used in precision manufacturing. These machines use touch probes or laser scanners to capture the geometric characteristics of a part and compare them to the CAD model. CMM machines provide detailed information about the dimensions, form, and position of the part, ensuring that it meets the required specifications. These tools are essential for quality control and inspection in precision manufacturing.

Conclusion

Industrial-grade tools are the backbone of precision manufacturing, providing the accuracy and reliability needed to produce high-quality products. From machining tools to 3D printing technology and precision measurement tools, these tools are essential for meeting the demands of modern manufacturing processes. By investing in industrial-grade tools, manufacturers can ensure consistent and precise production of parts, leading to improved efficiency and quality in precision manufacturing.

For more information on industrial-grade tools for precision manufacturing, contact us today!