Innovative Industrial Machinery for Enhanced Productivity

- 0

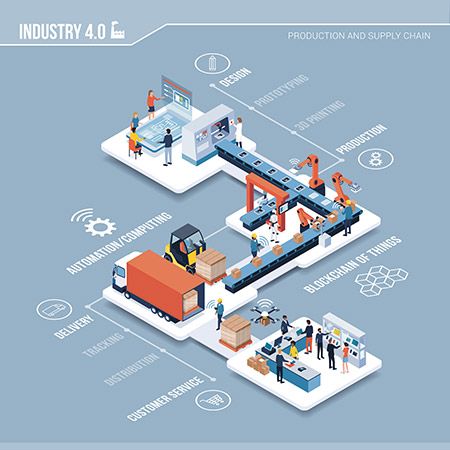

As technology continues to advance at an unprecedented rate, the industrial machinery sector is no exception. With the introduction of cutting-edge technologies such as artificial intelligence, Internet of Things (IoT), and robotics, industrial machinery has undergone a significant transformation in recent years. These innovative technologies have paved the way for enhanced productivity, improved efficiency, and increased profitability for businesses across various industries.

Artificial Intelligence in Industrial Machinery

One of the most significant developments in the industrial machinery sector is the integration of artificial intelligence (AI). AI-powered machinery is capable of learning and adapting to its environment, making autonomous decisions, and optimizing processes in real-time. This has revolutionized the way industrial operations are carried out, leading to higher accuracy, speed, and overall productivity.

Benefits of AI in Industrial Machinery

Improved predictive maintenance: AI-powered machinery can analyze vast amounts of data to predict potential failures before they occur, reducing downtime and maintenance costs.

Enhanced quality control: AI algorithms can identify defects and anomalies in products with high precision, ensuring consistent quality standards.

Optimized production schedules: AI can optimize production schedules based on real-time demand and resource availability, maximizing efficiency and profitability.

Internet of Things (IoT) in Industrial Machinery

The Internet of Things (IoT) has also played a crucial role in enhancing productivity in the industrial machinery sector. IoT-enabled machinery can communicate with each other and with central systems, exchanging data and insights that help streamline operations and improve decision-making.

Key Features of IoT in Industrial Machinery

Remote monitoring and control: IoT devices allow operators to monitor and control machinery from anywhere, enabling real-time adjustments and troubleshooting.

Predictive analytics: IoT sensors can collect data on machine performance and environmental conditions, enabling predictive maintenance and optimization of production processes.

Energy efficiency: IoT-enabled machinery can automatically adjust energy consumption based on demand and availability, reducing costs and environmental impact.

Robotics in Industrial Machinery

Robotics technology has revolutionized the manufacturing industry, enabling automation of repetitive tasks, increasing production speed, and improving worker safety. Industrial robots can perform a wide range of tasks with precision and efficiency, leading to higher productivity and cost savings for businesses.

Advantages of Robotics in Industrial Machinery

Increased speed and accuracy: Robots can perform tasks faster and more accurately than human workers, reducing cycle times and improving product quality.

Enhanced safety: Robots can handle hazardous materials and work in dangerous environments, reducing the risk of injuries for human workers.

Flexibility and scalability: Industrial robots can be easily reprogrammed and reconfigured to adapt to changing production needs, providing flexibility and scalability for businesses.

Conclusion

Innovative technologies such as artificial intelligence, Internet of Things, and robotics have revolutionized the industrial machinery sector, enabling businesses to achieve higher levels of productivity, efficiency, and profitability. By embracing these technologies and investing in cutting-edge machinery, companies can stay ahead of the competition, optimize their operations, and drive growth in today’s fast-paced market.

Are you looking to enhance productivity in your industrial operations? Contact us today to learn more about our innovative industrial machinery solutions and how they can benefit your business.